Residual Stress Measurement: Residual stresses influence the behavior of mechanical components and can impair the structural and dimensional stability, as well as the fatigue and fracture resistance of components. A residual tensile stress actually facilitates crack propagation and therefore reduces the fatigue life of a mechanical component. Residual stresses limit the loading capacity and safety of mechanical components during operation and in certain circumstances it is necessary to be able to quantify those stresses. Durham Instruments offers Residual Stress Measurement systems by a well developed hole drilling method, in a manual or automated process. We have the solution to improve your unique application!

RESTAN-MTS3000

The MTS3000 or RESTAN (Residual Stress Analyzer) is an...

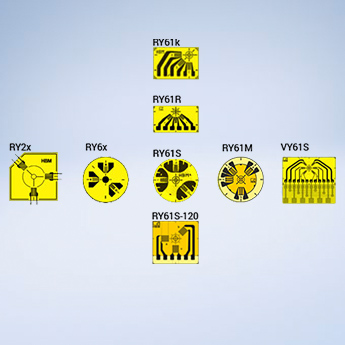

XY/RY Strain Gauges for Residual Stress Measurements

Determining residual stresses in materials (e.g. during casting, welding and forming processes) becomes easy with HBM's special strain gauges. These special strain gauges for residual stress analysis are available for precise and safe high-speed...