Signal Conditioning

ClipX Industrial Signal Conditioner

ClipX – The Precise and Easy-to-Integrate Industrial Signal Conditioner

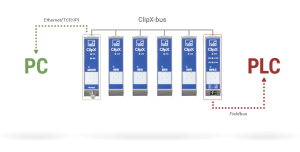

With an accuracy class of 0.01 and an integrated calibration certificate, the interference-proof signal conditioner ClipX is setting new standards in industrial process control. ClipX adapts to your measurement task, regardless of whether it is used with single- or multiple-channel applications, in manufacturing machines, in test benches or for production monitoring. Owing to the Plug and Play principle, up to six devices can be plugged simultaneously in a modular setup and the measured data can be pre-calculated. Unlike conventional measuring signal conditioners, ClipX does not require a separate head module for direct data processing.

ClipX provides all the latest automation interfaces to perfectly integrate the device into comprehensive control concepts. A particular feature is the intuitive web interface that also enables remote operation, parameterization, and diagnosis.

- Accuracy class: 0.01

- Measurement inputs: Full-bridge and half-bridge strain gauges, piezoresistive transducer, potentiometer, Pt100, current, and voltage

- Interfaces: PROFINET, EtherCAT®,PROFIBUS, Ethernet/IP™*, analog (V/mA,) digital-I/O, and Ethernet (TCP/IP)

- IIoT (Industrial Internet of Things): Remote diagnosis, Health monitoring and web integration

Precise and interference-proof

- Fast and digital signal conditioning for force sensors, load cells, torque sensors, pressure transducers, as well as temperature and standardized signals (current/voltage)

- Guaranteed measurement accuracy, even in harsh industrial environments with electrical interferences

- Full traceability owing to EN10204-compliant calibration records that are directly stored in the device

- In combination with the SD01A Zener barrier , sensors can also be operated as intrinsically safe devices in potentially explosive atmospheres, measurement circuit type (Ex II (1) GD, [EEx ia]IIC).

Reliable results and trustworthy acquisition of mechanical and electrical quantities in industrial environments

Faster industrial processes

- A high sample rate and high bandwidth facilitate for easy use in automation environments

- Quick setup and diagnosis using the display on the device and the intuitive web interface

- Full support of TEDS (Transducer Electronic Data Sheet)

- ClipX-bus allows transmission and computation of measured values between up to 6 devices

- Interfaces: PROFINET, EtherCAT®, PROFIBUS, Ethernet/IP™, analog (V/mA,) digital-I/O, Ethernet (TCP/IP)

- Integrated OPC-UA server (available from version 3.0)

Easy setup with integrated web interface, time- and cost-saving remote diagnosis, and automated channel parameterization of the measurement chain (TEDS) or the integrated Adjustment Assistant that guides the user step by step

Efficient and profitable

- Individual system setup and compact design

- Easy and safe assembly without tools

- Transmission of measured values in millisecond intervals using the ClipX-bus

- Mathematical and technological calculation channels (Smart Functions) allow signal conditioning/analysis and easy parameterization

- Individually configurable input/output signals and fieldbus interfaces

- All the device settings can be individually configured via the Ethernet and fieldbus interfaces and the internal object directory

- Open to integration with many other software programs: LabVIEW, Visual Studio .NET under Windows as well as Linux

Unbeatable price-to-performance ratio and a future-proof investment because of the open automation standards

Intuitive Web Interface

ClipX comes with an innovative and intuitive web interface and is immediately operational without any software installation or training.

- It can be used on all browser-based devices (and also mobile devices)

- Touchscreen control with three-level user administration

- Remote maintenance via a company network or the Internet

- The web interface can be used on mobile devices using a WiFi router

- Create your own customized display pages

- Multilingual user interface with integrated help and adjustment assistant

Individual System Setup

ClipX allows for the synchronization of both individual measurement chains and systems in milliseconds – optionally with a simultaneous PC or fieldbus connection.

- Measured values including their status (diagnosis) are transmitted via the ClipX bus

- No head module is required, which reduces costs

- Direct processing of all signals such as summation, peak values, or controls

- The multi-client capability enables all interfaces to be used in parallel and in real time

- Digital inputs and outputs can perform fast control and monitoring tasks (e.g. alarms)

The Industrial Internet of Things (IIoT)

ClipX already meets the requirements of the future IIoT.

- Easy amplifier parameterization via TEDS or the smart Adjustment Assistant

- Smart devices owing to Smart Functions (diagnosis and analysis)

- Non-interacting, parallel operation of the PLC, the system PC, and the service interfaces

- High forward-compatibility and investment security due to flexible automation interfaces and data logging to the Cloud (OPC-UA protocol on request)

ClipX accessories:

The ClipX measurement signal conditioner comes with the following free accessories:

- ePLAN macros available for free download

- 3D model (STEP files)