Strain Gauges

Showa Strain Gauges – general specifications

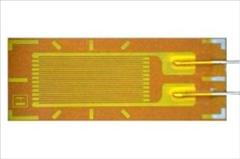

Basic Structure

Strain gauges are made with a metallic foil film in the thickness of a few microns is glued on a thin electrically insulated sheet (such as polyimide, polyester and so on). This foil film is cut down by photo-etching method in the shape of strain gauges which can be made with the negative film masks of the strain gauge patterns. These photo-etched strain gauge patterns are trimmed to have a standard resistance value satisfying requirements as the strain gauges. In addition, for strain gauges in general applications, thermal resistance factors of the foil films are controlled to have three categories to match with the thermal elongation factors of 3 major and most popular materials of mild steel/11ppm, stainless steel/16ppm and aluminum alloy/23ppm, for which our strain gauges can be self-temperature compensated to minimize temperature effects if specified when ordering.

Standard Specifications

The strain gauges are available with two different backing materials, namely, one is the polyester FA series and the other is the polyimide MA Series. The FA Series are available in many different variations, and therefore are most suitable for a wide range of strain measurements in general. On the other hand, the MA Series are suitable for strain measurements at medium and high temperatures and for use as elements in various industrial or scientific sensors.

Please click on the PDF to review the data sheet for general specifications.