Optical Strain Sensors

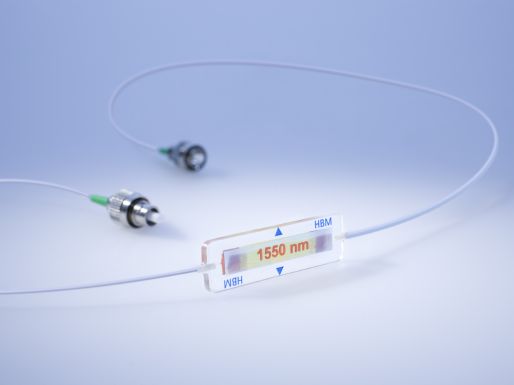

OL – Optical Strain Gauge

The optical strain gage OL is made from fibers of glass with a very small core diameter of no more than 5 micrometers. In comparison, the diameter of human hair ranges from 60 to 80 micrometers. The fiber core is surrounded by a cladding layer from purest glass with a diameter of 125 micrometers.

The optical effect that is used for strain measurement is because of the distance of the reflection points and therefore the wavelength of the reflected light being changed by the induced strain.

Like all sensors based on Bragg gratings OL has the following advantages:

* Insensitive to electromagnetic fields

* Can potentially be used in highly explosive atmospheres

* Suffer no mechanical failure of sensor material (glass) under high vibration loads

* Reduced numbers of connection lines and hence less impact on test objectives

* Low interconnection needs as numerous sensors with different Bragg wavelenghts can be included in one fiber

* 10 million load cycles at ±3.000 µm/m alternating strain

Previously, installation of a glass fiber with Bragg grating on a test object was implemented with adhesive glue being applied either side of the Bragg grating. The glass fiber must therefore be pre-strained to measure negative strains (compressions) as well. This means that the measurement range in the negative strain direction is limited, as it exactly corresponds to the direction and value of the pre-strain. Because the Bragg gratings are located inside the fiber, pre-straining and installing the gages can cause unwanted damage to the fiber.

This is where the advantages of the optical strain gage OL come to the fore, because the glass fibers with the Bragg gratings are symmetrically embedded in the composite material. Thanks to this patented design, both positive and negative strains can be induced in the Bragg grating.

HBM patented optical strain gages utilize proven technology, and are easy to work with.

There is no difference in the handling of optical or traditional (electrical) types of strain gages. You don’t have to learn new skills: Bonding, covering, connecting, etc. are all identical. The patented design protects the fiber and makes configuring your test setup quick and convenient. Benefit from both optical sensor technology and the wide range of accessories for electrical strain gages.

Best of both worlds

HBM’s measurement technology enables the simultaneous acquisition of data using both electrical and optical strain gages. The EasyOptics module in HBM’s catman®AP software enables you to jointly acquire and analyze data from different types of sensors.