Software

Type 8440 (Replaces Type 8740) BK Connect Angle Domain Analysis

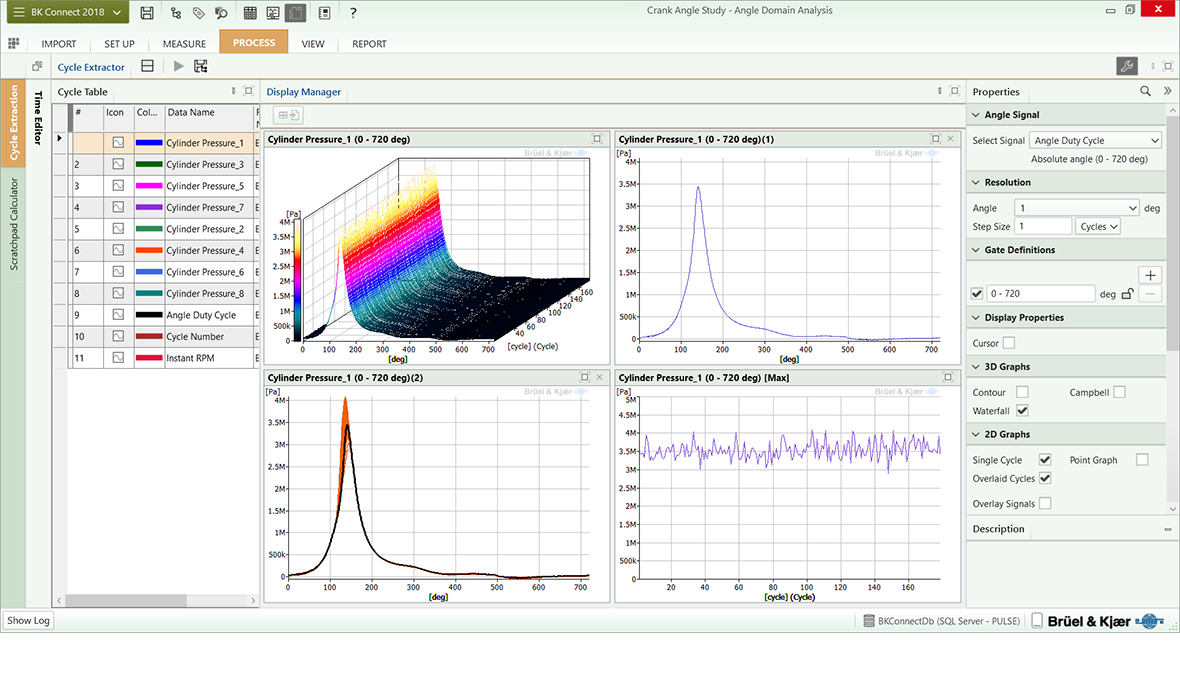

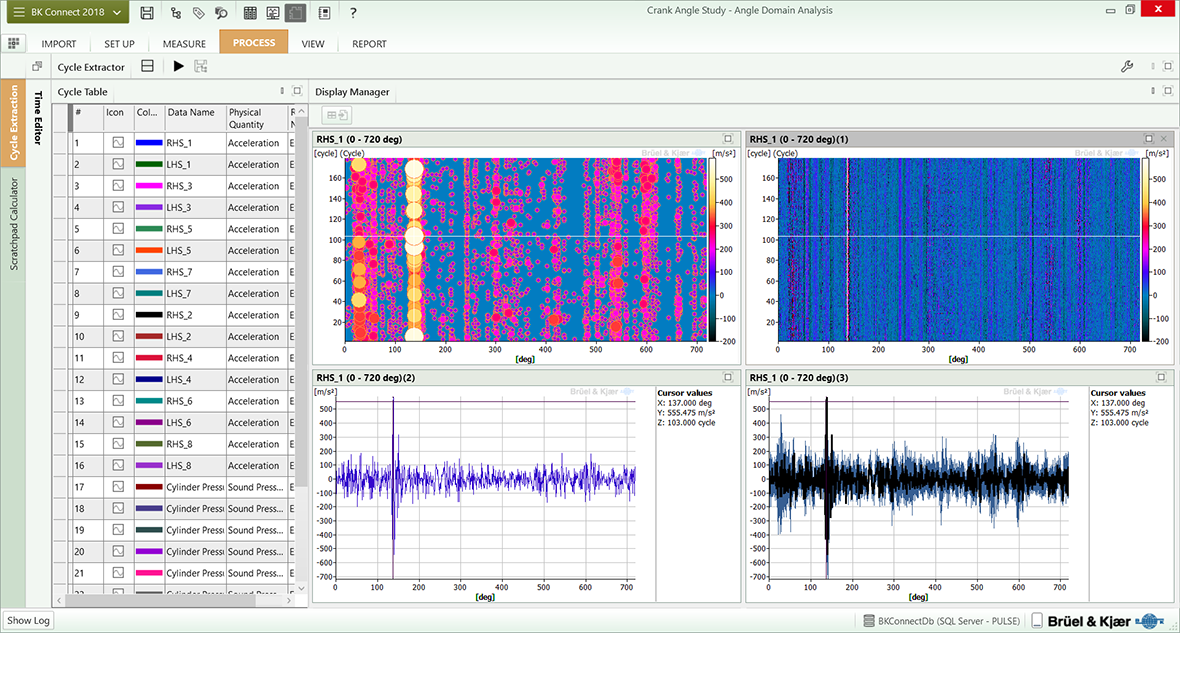

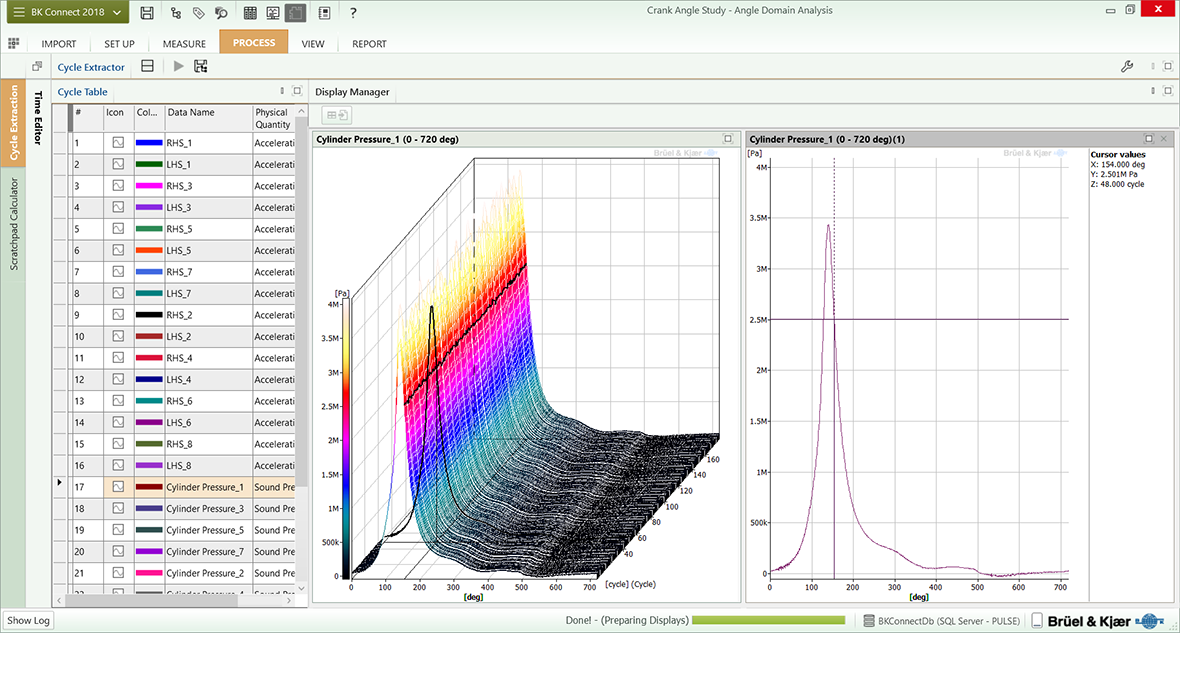

This application takes recorded time data and resamples it so that it can be presented as a function of the rotation angle during the duty cycle of rotating machines, such as car engines. By relating sound and vibration data to the angle of the engine’s crankshaft or flywheel, it is easy to see correlation with the position in the engine’s cycle. This new perspective gives insights into noises that arise from cyclic phenomena, such as the firing of a particular cylinder, or vibrations from a certain point in the engine’s duty cycle.

USE SCENARIOS

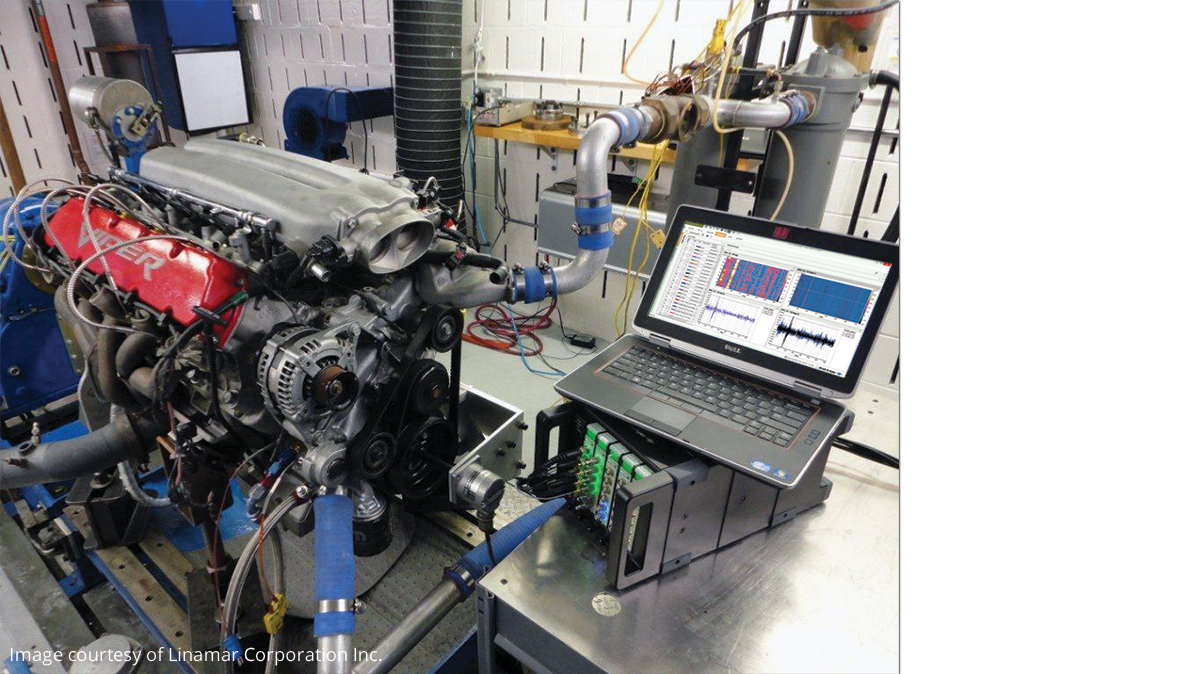

- Analysis of power train sound and vibration in relation to crankshaft angle for noise, vibration and harshness (NVH) engineering

- Identifying gear noise in low-friction gearboxes

- Reducing noise from imbalance in two- and three-cylinder engines

- Comparison of angle-domain data sets from different test runs

This angle-domain processing software works with any signal, or combination of signals, that gives the duty cycle period. This can be a tacho pulse signal from a shaft encoder or a magnetic pickup on a flywheel, or a top dead-centre (TDC) signal from a flywheel or test-bed encoder, or from an engine control unit.

By resampling raw time-data from the time domain so that it corresponds directly to the position of a rotating component, it gives automatic and unequivocal identification of where sound and vibration events occur in an engine’s cycle – instead of corresponding only to the time intervals at which the data was originally measured. For example, during crank-angle analysis on a 4-stroke engine, the data is sampled in relation to the 720° (two complete revolutions) that comprise a complete duty cycle.

CAPABILITIES

- Statistical analysis of cycle-related phenomena

- Cycle statistics: minimum, maximum, mean, RMS and peak-peak values per cycle, vs time or RPM

- Contour, waterfall and Campbell plots of cycle history vs time or RPM

- 3D displays of cycle vs time or cycle number

- 2D displays of cycles (either overlaid or single)

- Gated statistics vs cycle number

- Duty cycle extraction with fixed-angle increments

- Ability to apply offset for TDC correction based on TDC signal or missing pulses (tacho repair)

- Integrated Microsoft® Office reporting capabilities

Combining this application with BK Connect Time Data Recorder Type 8402 makes Time Data Recorder tasks available within the Angle Domain Analysis application.

REQUIREMENTS

This application requires BK Connect Data Viewer Type 8400. Type 8400 is free.