Software

Type 7883 Earth-Moving Machinery Noise Software

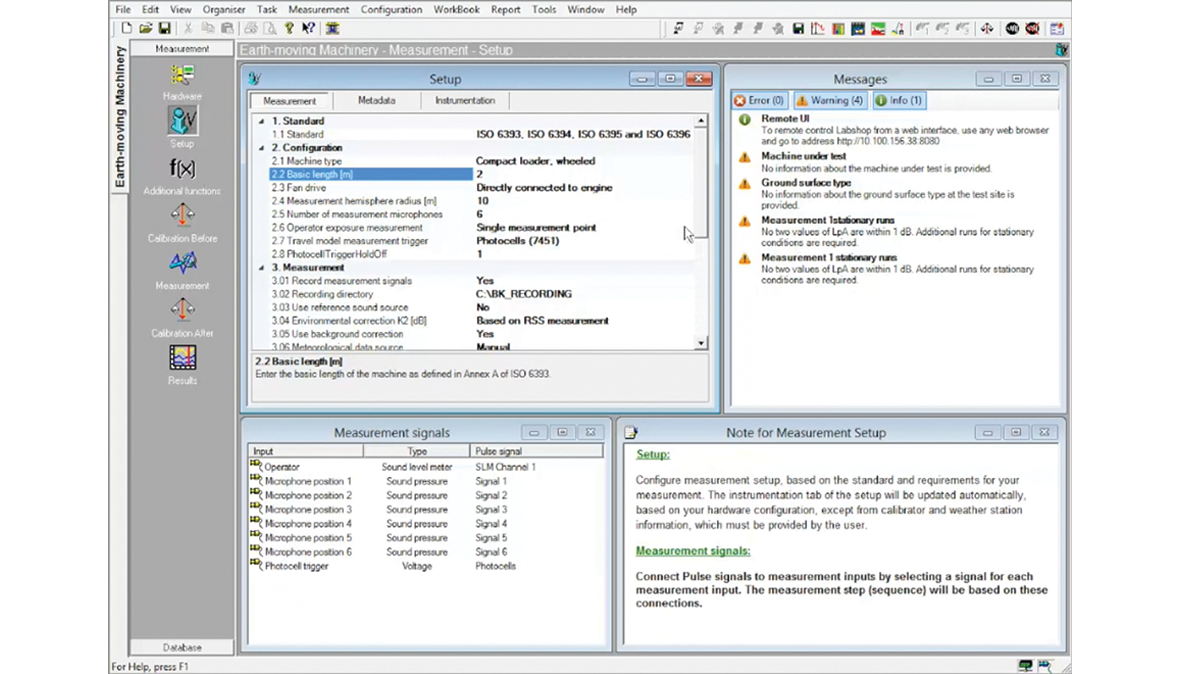

This PULSE software determines the official noise levels of earth-moving machinery by guiding the user through the necessary steps to meet ISO measurement standards. It works together with six microphones that are positioned on an imaginary hemisphere surrounding the test object, and a weather station. For some tests, an extra microphone records acoustic levels at the operator’s position. The software controls the test and helps the user ensure it meets the relevant measurement standard with clear step-by-step instructions through set up, calibration, measurement and reporting of noise emission quantities according to ISO 6393, ISO 6394, ISO 6395 and ISO 6396.

USE SCENARIOS

- Operational noise determination of backhoe loaders, diggers, excavators, dumper trucks, dozers,

- Research and development measurements to ensure designs are on-track

- Tests using limited personnel

- Official declaration of machinery noise levels to authorities

EASE OF USE

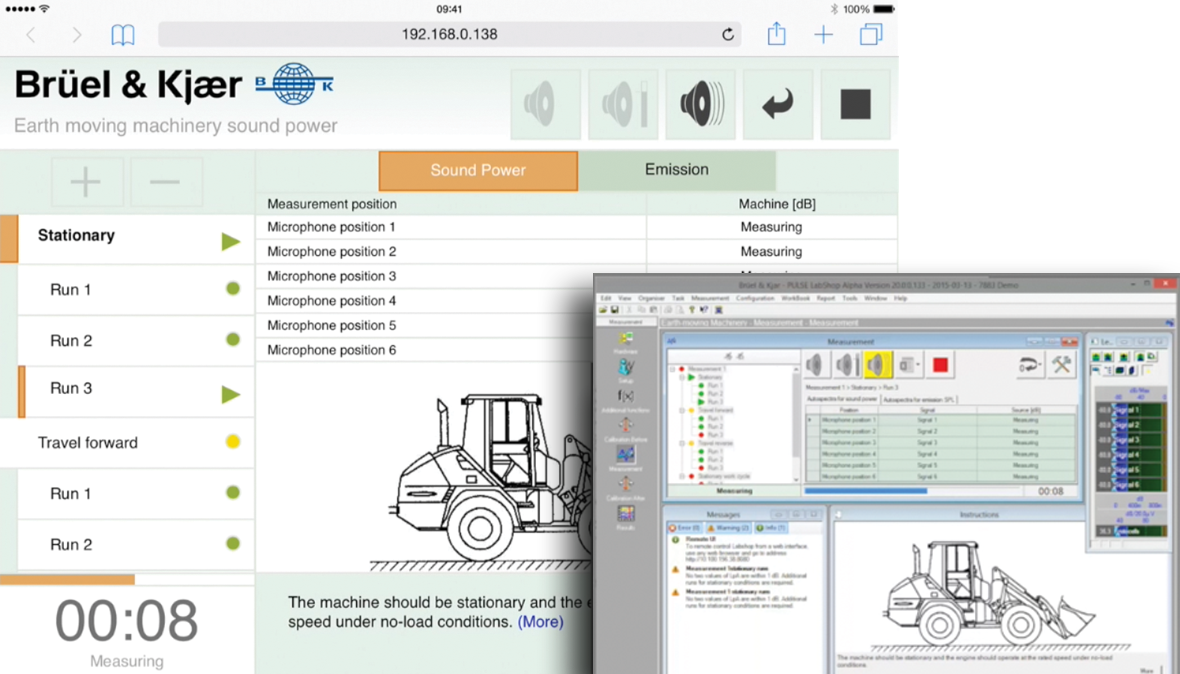

This PULSE software is an application template designed for easy determination of the sound power of earth-moving machinery. The software is configured with the requirements of each standard and displays warnings if information is missing or does not follow the requirements. The operator can check the health and readiness of all channels simultaneously with one click, using charge injection calibration (CIC). Users need minimal training and can operate the application from a tablet. This makes it easy to use the system alone, as the operator of the vehicle also controls the measurements.

CAPABILITIES

- Remote control of test via mobile devices

- Dynamic measurements of operating machinery

- Single-person operation

- Full documentation and statistics for all measured machines

- Automatic generation of test reports

DYNAMIC MESUREMENTS

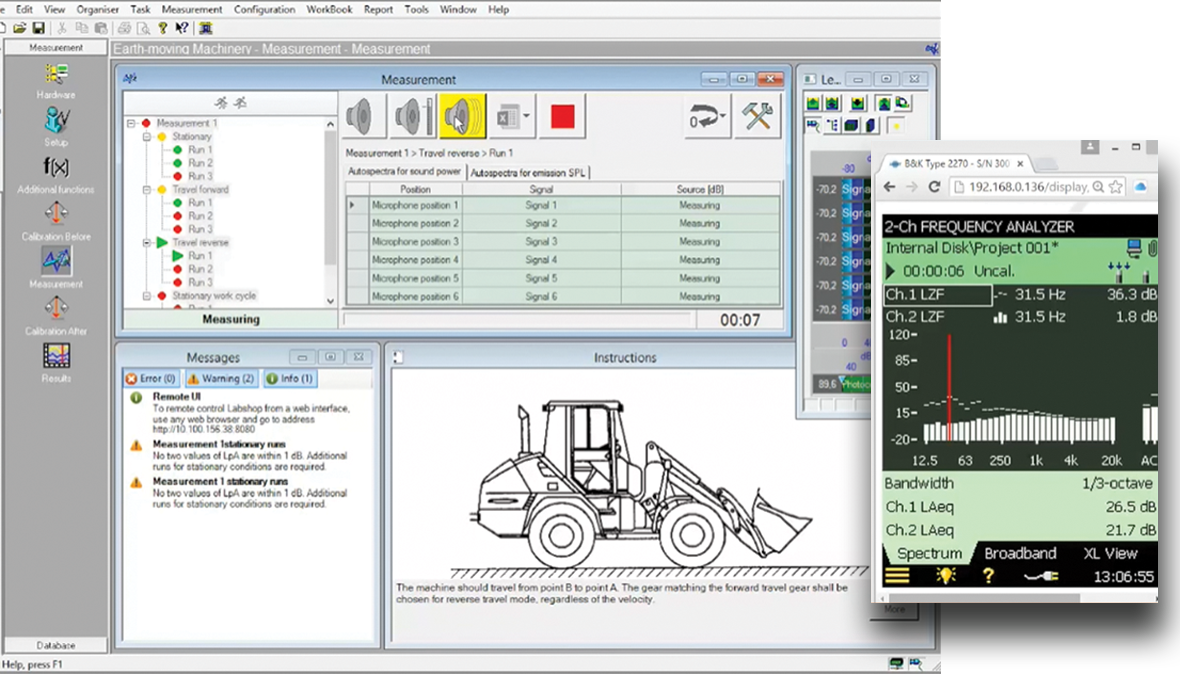

For dynamic measurements taken while the machinery operates, photocells are incorporated into the system to trigger measurements from the machinery’s movements. A sound level meter in the vehicle acquires data at the operator’s position, and a wireless connection transfers the data to the software via an acquisition station on the ground outside.

The sound power of machines is calculated from the measured sound pressure during specified modes of machine operation.