Software

Type 7882 Product Noise Software Using Sound Intensity

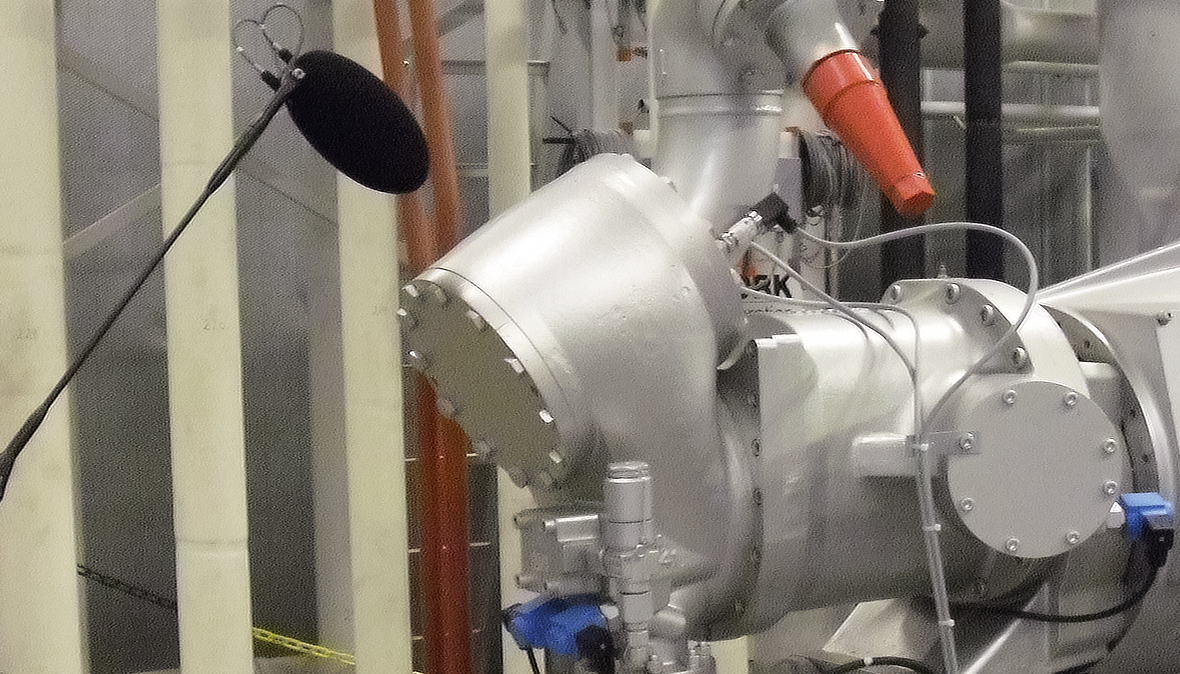

This PULSE software determines the noise levels of products by measuring their sound intensity with a hand-held sound intensity probe. The user measures the sound on a flat, virtual surface on every side of the test object, at a very close distance. Because the acoustic measurements are so close to the source, the sound intensity technique can easily work despite background noise. This makes it ideal where the sound field is neither free nor reverberant, for in situ measurements, and where background noise prevents sound pressurebased measurements.

The software helps the user measure sound power using measurement methods that fulfill the standards ISO 9614–1, ISO 9614–2 and ISO 9614–3.

USE SCENARIOS

- Developing quieter products

- Determining product compliance with noise specifications for legislation or voluntary awards such as Germany’s Blue Angel

- Comparing noise emissions of machinery and equipment for benchmarking

- Locating and ranking noise sources

EASE OF USE

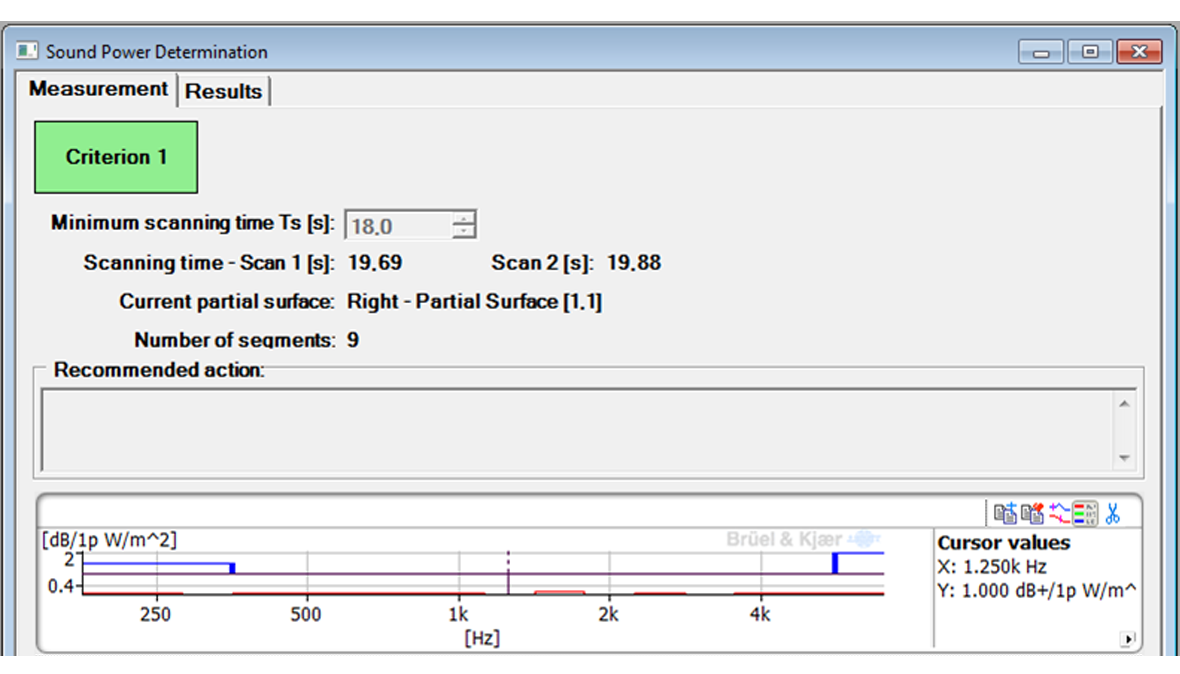

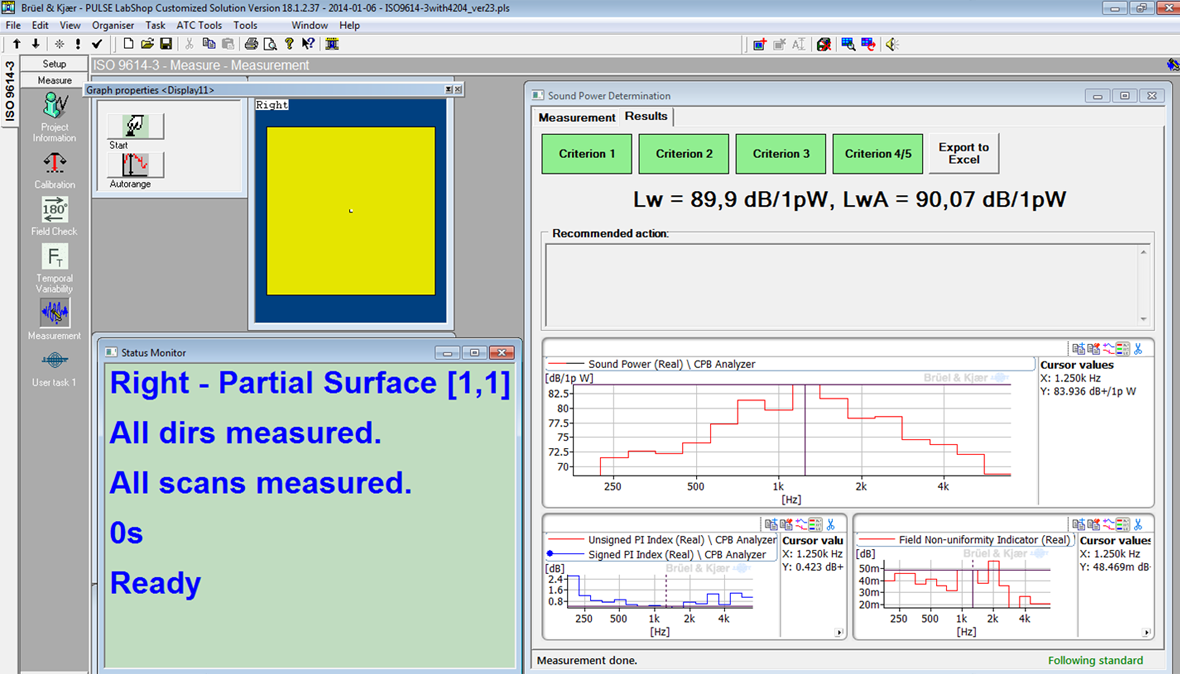

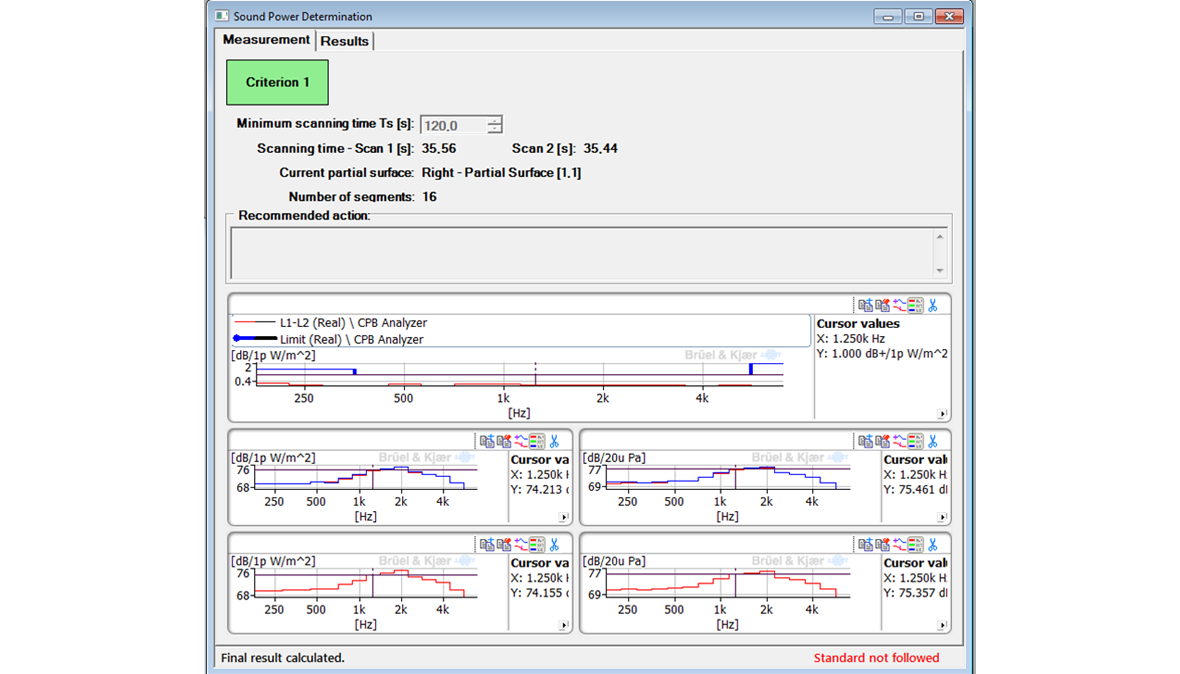

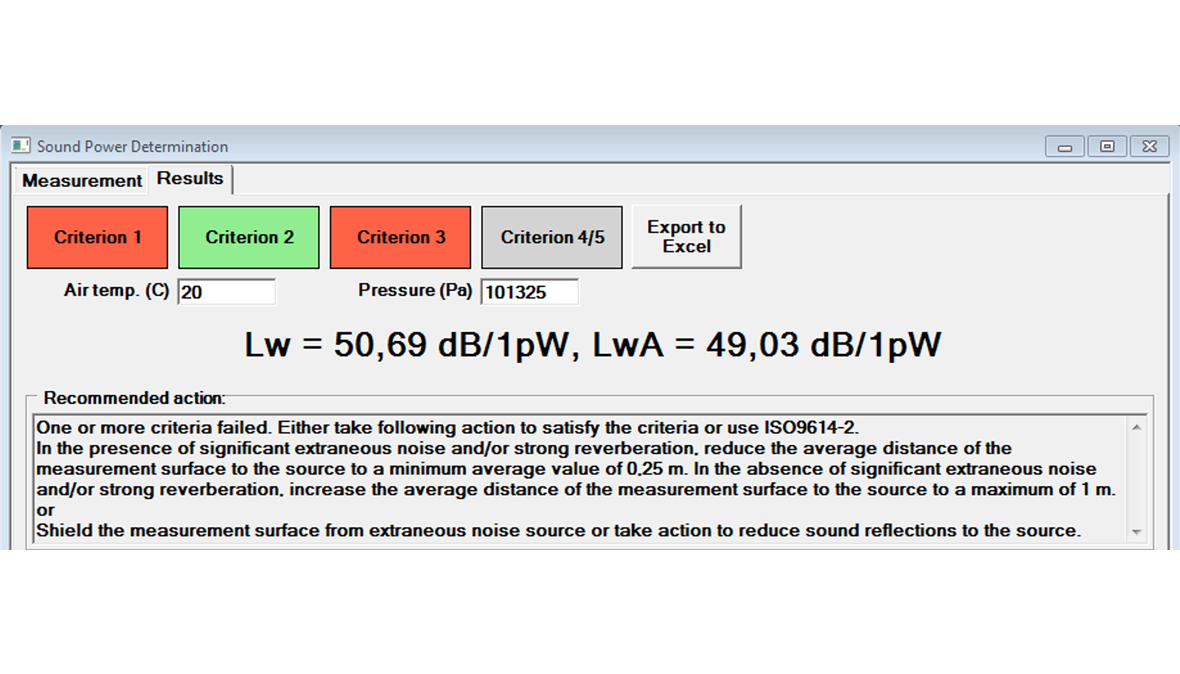

This PULSE software is an application template designed for easy determination of sound power using sound intensity. A dedicated user interface for each ISO standard has a clear task list that leads you through all the necessary steps to fulfil the requirements. Features, such as pop-up text and colour coding give quick updates on measurement status, and the software displays clear warnings if information is missing or does not follow the requirements. Based on the results, actions are suggested to attain the desired level of accuracy. The operator can check the health and readiness of all channels simultaneously with one click, using charge injection calibration (CIC). Users need minimal training, which makes it easy to use the system alone.

PLANAR SURFACES

For each of the flat surfaces around the test object, the software averages the sound intensity and measures the sound pressure, pressure-residual intensity index, and the dynamic capability index. The user can easily add new planar surfaces, and segment previously defined surfaces up to seven times to obtain the desired accuracy. With this technique it is possible to locate and rank noise sources for each measurement surface.

CAPABILITIES

- High-frequency corrections to intensity spectra to enable measurements at 6.3 kHz, 8 kHz and 10 kHz 1/3-octave bands

- ISO 9614–1 uses sound intensity measurements at discrete points

- ISO 9614–2 uses sound intensity measurements with a scanning method

- ISO 9614–3 uses a precision sound intensity scanning method

- Data and results saved to Microsoft® Excel® for customized reporting and further post-processing

- Allows users to skip repetitive tasks