Vibration Controllers & Software

Sine Vibration Control

Sine control creates excitation with analog-quality drive signal and user-programmable sweep parameters. This test profile is particularly useful for studying the structural dynamics of the device under test, as it enables accurate measurement of dynamic response at resonances. Since sine control concentrates all the vibration energy at a single frequency, it is also suitable for fatigue testing.

USE SCENARIOS

- Swept-sine and stepped-sine testing to meet MIL-STD, DIN, ISO, IEC and other standards

- Structural dynamics characterization

- Durability and fatigue testing

CHARACTERISTICS

A sine test entails using the host PC to enter configuration parameters into a simple breakpoint table consisting of acceleration, velocity, displacement amplitudes and their associated frequencies, as well as slope segments.When slopes are used, crossover frequencies or AVD amplitudes should automatically be calculated.

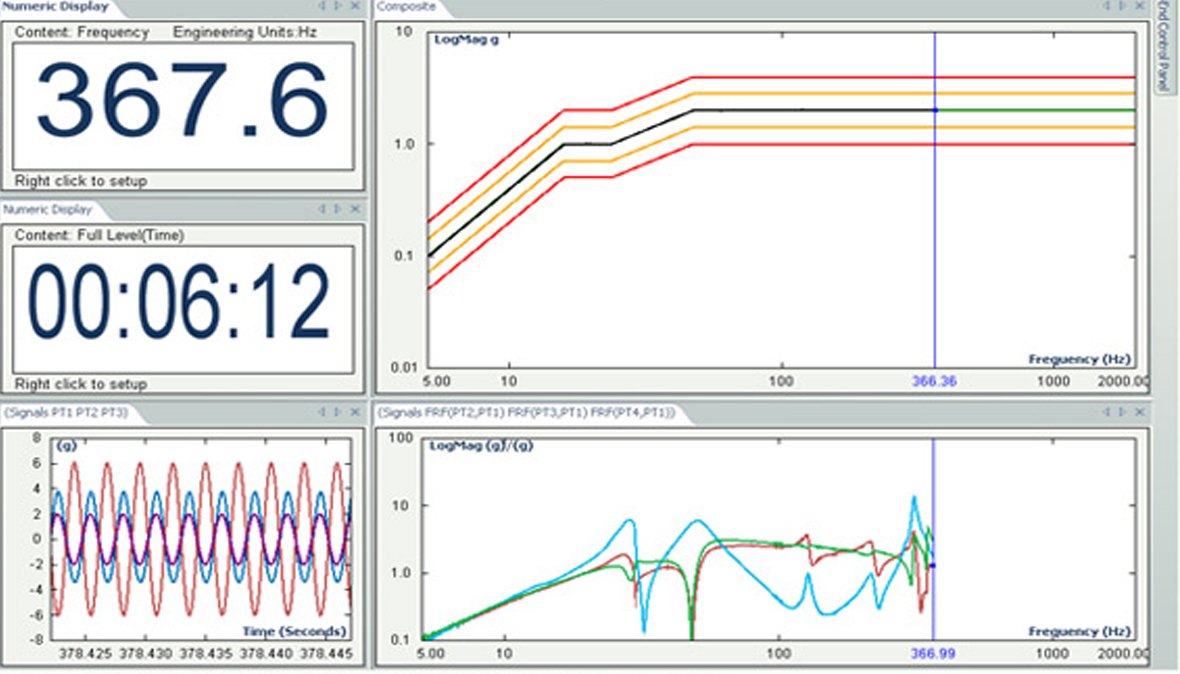

The profile is usually displayed on a plot as the breakpoint table is created. The maximum peak values for acceleration and velocity, as well as the maximum peak-to-peak displacement for the test should also be displayed.

The sine test includes a pre-test that identifies the system transfer function. Fast loop times around 10 ms are important for accurate control, even with high Q resonances.

Digital tracking filters with frequency-proportional or fixed-bandwidth filters are usually included. A frequency range will be specified, say 0.1 Hz to 12,000 Hz. Real-time magnitude- and phase-FRF measurements may be performed on a defined number of points, typically up to 2048.

To prevent malfunctions or damage to the device under test and to the test system, the user is automatically warned if the dynamic demands of the test exceed the shaker’s operating limits.