K-OP: Configurable Optical Sensors Chain

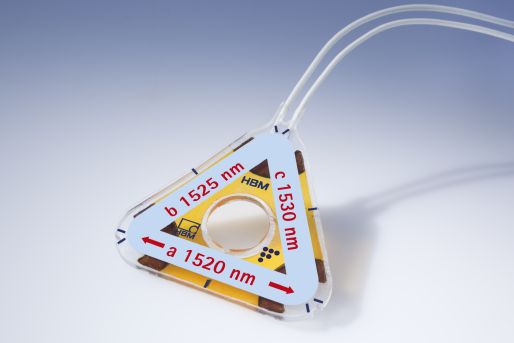

OR Optical Rosette Strain Gauge

Precise results – even in adverse environments

Since optical strain gages do not require any electrical signals, they open up new opportunities for use in experimental stress analysis. Unlike linear optical strain gages, K-OR – comprising three strain gages – measures strain in three directions. This enables the absolute value and direction of mechanical stresses to be determined in the same way as with electrical strain gages. Specially tested for applications with a strain of +/- 5000 µm/m and 10 million load cycles, K-OR in addition withstands extremely adverse ambient conditions.

The optical rosette is highly suitable for measurements

* In potentially explosive atmospheres

* In areas where there is high voltage or

* Powerful electromagnetic interference as well as for

* Materials testing, for example, on the rotor blades of wind power plants.

Easy installation and fast wiring

The installation effort of optical strain gages such as K-OR is similar to that of electrical strain gages. Wiring, however, is less complex, because optical strain gages enable multiple sensors to be connected in one optical fiber.

Measuring chain for optical sensors from a single source

HBM provides the complete measuring chain for optical sensors from a single source. Ranging from the strain gage through interrogators and multiplexers to software. Determine stresses on components and in environments where conventional technologies are coming up against their limits – using HBM’s optical measuring chain. Go to the measuring chain for optical sensors