Shakers & Exciters

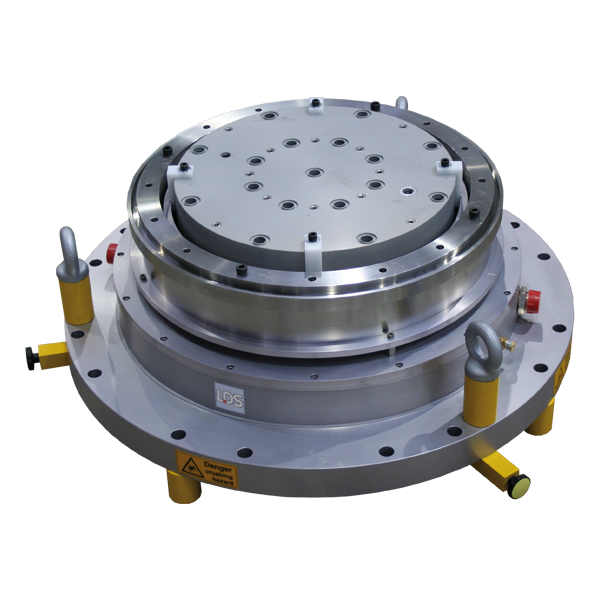

LDS Fixtures Head Expanders And Thermal Barriers

Part of many vibration test systems, a head expander consists of a large platform that is bolted to the shaker’s load table to increase its effective mounting surface and enable it to test larger or more numerous payloads than those that can be attached to the load table alone.

A thermal barrier protects the shaker from high temperatures, for example when operating in conjunction with a climactic chamber during environmental tests. Depending on your testing needs, thermal barriers can be used with or without head expanders.

All of our medium- and high-force shakers (with armature diameters from 335 to 640 mm) can be fitted with a variety of standard head expanders and thermal barriers.

USE SCENARIOS

- Increasing the effective mounting surface of a shaker’s armature

- Accommodating larger, bulkier payloads

- Increasing the quantity of articles that can be tested at one time, reducing total testing times

- Providing increased flexibility in fixture design

CHARACTERISTICS

Designed using finite element analysis (FEA) technology, LDS®Head Expanders are cast from a high-strength, aerospace-grade magnesium alloy with excellent damping properties to minimize force dispersion. They have a usable frequency range from DC – 2000 Hz. To prevent corrosion, non-machined parts are painted and machine parts are coated with lubricant.

We offer two types of head expander as standard products: guided and unguided. Guided head expanders enable you to test payloads with masses greater than those the shaker alone can support. Alternatively, unguided head expanders allow you to test payloads whose dimensions exceed those of the shaker’s armature work surface.

Guided head expanders are available for LDS® V875, V875LS, V8, V9x shakers (whether trunnion- or combo-mounted). They are 1200 mm2 in size and have a support capability up to 1200 kg.

Unguided head expanders for the V850, V875, V875LS, V8 and V9x come in four sizes: 610, 762, 1000 and 1220 mm2 – for model V830-335, a 610 mm2 expander is available. As they are intended to accommodate larger, not heavier, articles, unguided head expanders do not provide additional load support.

For immediate testing, all head expanders are supplied complete with fasteners and fitting tools, including keyed payload attachment inserts in both grid and armature patterns, as well as armature screws, dedicated wrench key and torque wrench, and lifting eye-bolt.

Additionally, thermal barriers reduce heat conductivity between payload and shaker (or, slip table, if one is used), thus enabling vibration testing systems to operate with climactic chambers for environmental tests. We offer thermal barriers to match all sizes of head expander in the LDS range; other insert patterns can be supplied to special order.