Electric Power Testing

eDrive Power Meters and Analyzers – Overview

The eDrive Power Meter and Power Analyzer packages are tailored for power measurement at inverters and inverter driven machines. Thus, they utilize high sample rates and both electrical as well as mechanical power calculation capabilities.

Power Meters and Power Analyzers to Test Inverter Driven Electrical Machines

The HBM eDrive series of Power Meters and Power Analyzers are both with unparalleled power computation based on digital cycle detection. Thus, they deliver reliable results also in dynamic load changes, where conventional power meters just fail. With enough sample rate to cover all current inverter technologies, they can be expanded with more channel, higher sample rates, or other inputs to match every need you might run into in the future.

- 3 to 51 power channels per mainframe

- Simultaneous acquisition of electrical, mechanical and bus data

- Real time result transfer to automation system and real time raw data storage

Accurate

- Accuracy 0.015% reading + 0.02% range

- High bandwidth >1 MHz

- Digital cycle detect for accurate results in static and dynamic tests

- Complete chain with “best in class” torque and current transducers

![]()

![]()

![]()

Flexible

- Grows from entry level 3 channel Power Meter to high end 51 channel Power Analyzer

- Electrical, mechanical, bus inputs

- Real time bus outputs

- Programmers API for system integration

![]()

![]()

Powerful

- Scalable computing power using on board DSPs

- Real time power calculation for any channel count

- Custom formulas

- Real time raw data storage

![]()

![]()

![]()

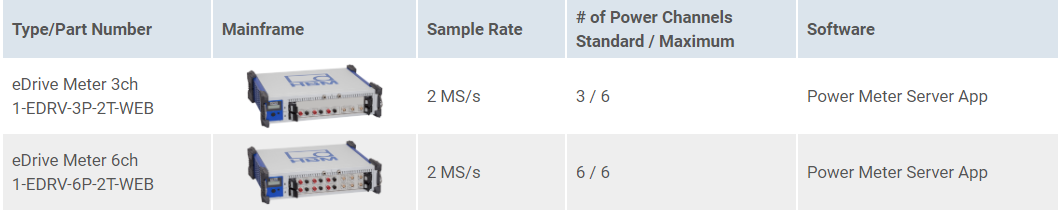

eDrive Power Meters for Entry Level Applications or System Integration

eDrive Power Meters offer 3 or 6 power channels and a sample rate of 2 MS/s; they come with an embedded POWER METER APP which enables them to be used with any device running a browser; connection is done using Ethernet connection.

Options include embedded SSD for raw data storage, CAN bus output, torque / speed connection box, artificial star adapter, current transducers, high voltage probes, and much more. Please order proper input cables for current and voltage when needed.

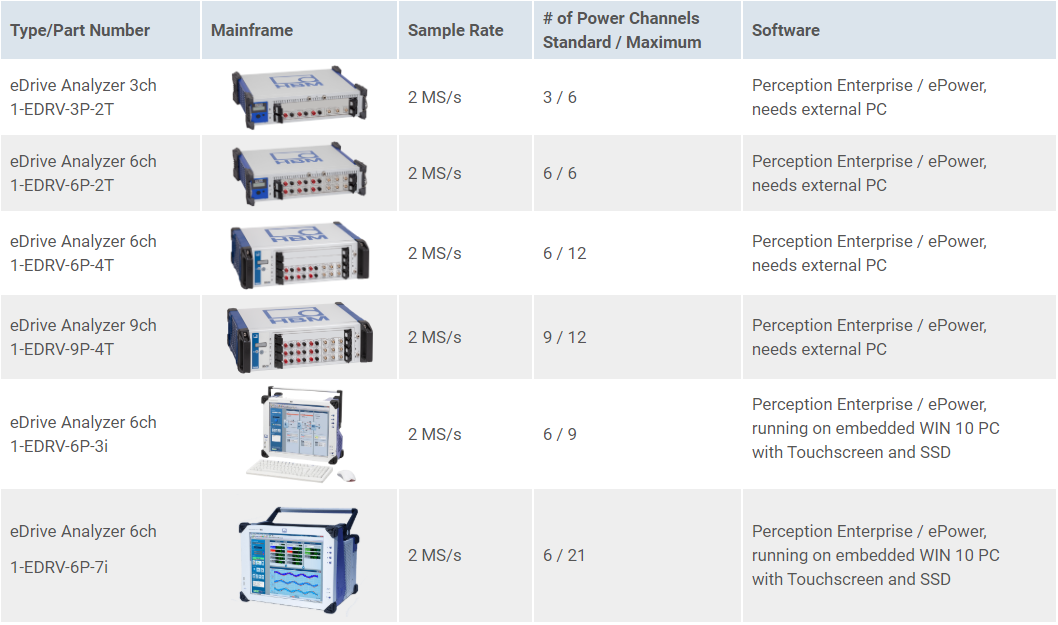

eDrive Power Analyzers for demanding R&D Applications and System Integration

eDrive Power Analyzers offer 3, 6 or 9 power channels with a sample rate of 2 MS/s; they can be expanded in channel count, or with mechanical inputs like acceleration or temperature, or with higher sample rate input boards. They use Perception Enterprise / eDrive software offering the usability of a POWER METER combined with the flexibility of a DAQ system. “t” mainframes are used using an external PC, while “I” system feature an integrated WIN10 PC.

Pending from the mainframe type, options include embedded SSD for raw data storage, more power inputs, other inputs for mechanical signals like acceleration or temperatures, CAN input and outputs, EtherCAT real time interface, torque / speed connection box, artificial star adapter, current transducers, high voltage probes, and much more. Please order proper input cables for current and voltage when needed.

eDrive Testing Brochure

(click for PDF):

Detailed Package Comparison Table

(click for PDF):

Power Analyzer Banner Specs:

(click for PDF):