Weighing

digiBOX weighing

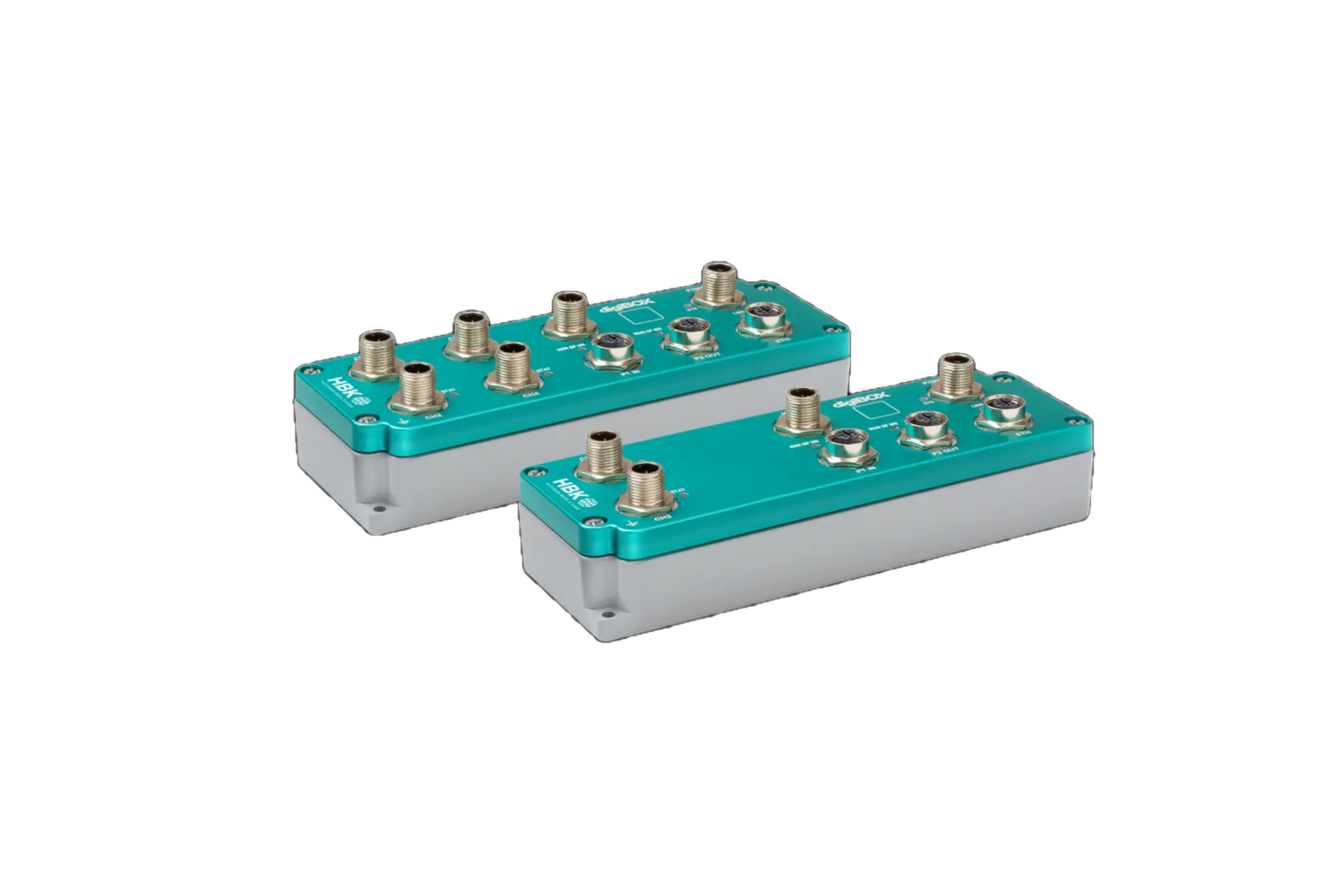

Description

The new and precise weighing electronic impresses with modern automation and cloud interfaces, an intuitive web server and integrated weighing algorithms for weight control and filling with parallel real time data processing.

Benefit from latest technologies:

- High quality measurements for load cells

- Integrated web server for easy-to-use parameterization and visualization with day and night mode

- OT connectivity for machine controls

- IT connectivity for data and process analysis and optimization

- Integrated weighing algorithms for fast and easy setup

- 10 parameter sets for pre-defined device settings

CHARACTERISTIC FEATURES

- Connection of load cells and strain gauge sensors (freely configurable 2 or 4 channels)

- 2kS/s sampling rate per strain gauge channel with 24-bit A/D conversion, synchronous measurements

- Robust and compact metal housing (IP67)

- 4 digital I/Os and 4 analog outputs (voltage/current switchable) or 8 digital I/Os

- Easy operation via the integrated web server

- Integrated weighing algorithms for weighing, check weighing, filling and container scales

- Sum channel with digital corner load adjustment

- PROFINET® (IRT/RT 2KHz), daisy-chain topology possible

- Parallel IT-level connection: TCP/IP-based protocols: openDAQ, MQTT, OPENAPI (RestAPI)

- Ethernet (TCP/IP): web server, openAPI (Rest), MQTT

Sensing Technology

digiBOX Weighing can be freely configured with (2-4) inputs for load cells and strain gauge-based sensors and features an input impedance of 80 – 5k Ohms, which allows for parallel wiring of multiple load cells. HBK provides a range of sensors for load measurement:

- Bending / beam load cell

- Canister load cell

- Compression / Tension load cell

- Single Point load cell

The sensor inputs are synchronized sample synchronous, enabling challenging weighing measurements with a 2 kS/s sample rate and 24-bit AD conversion.

Signal Processing

digiBOX weighing features a highly-configurable signal chain and integrated weighing algorithms for all types of weighing applications:

- 3-stage digital filter

- Flexible user-calibration

- Weighing functions

- Checkweighing algorithm

- Filling algorithm

- Sum channel

- Digital corner load adjustment

IT/OT connectivity

digiBOX Weighing offers parallel IT/OT connectivity, ensuring seamless integration with a machine’s PLC system while simultaneously making measurement data, calculated results and device parametrisation accessible to IT-level applications without compromising the ongoing PLC process.

This provides the IT-Level with critical process data from weighing processes, enabling new possibilities such

- historical data storage and tracking

- complex monitoring

- data acquisition (miniDAQ) and analysis

- building machine learning models

- digital twin applications

- Remote access and cloud integration

These capabilities are easily implemented using the integrated openDAQ™ protocol, which allows for streaming 2 kS/s sensor data and seamless integration into programming environments based on Python, C# and C++.

digiBOX Weighing Applications

digiBOX Weighing is ideally suited for Weighing applications (general weighing applications with up to 4 independent channels)

- Checkweigher (automatic weight capture, triggered via digital I/O or level)

- Filler (fully configurable filler application with up to 8 digital I/Os)

- Container scale (summation function for up to 4 channels with assistant for digital corner load adjustment)

- Silo scales

- Tank and hopper weighing systems

- Portable weigh bridges

- Pallet scales

- Platform scales

Specifications

| Number of inputs | Multi channel |

| Input | Piezo electric (charge), Strain gauge full bridge |

| Interface | EtherCAT, ProfiNet, TCP/IP, Digital IO, Analog |

| Accuracy class | 0.01 SG, 0.5 Piezo (charge) |

| Sample rate | 40000 S/s |

| Housing | Field mounted |

| Internal logic | Calculated channel |

| Legal for trade | No |